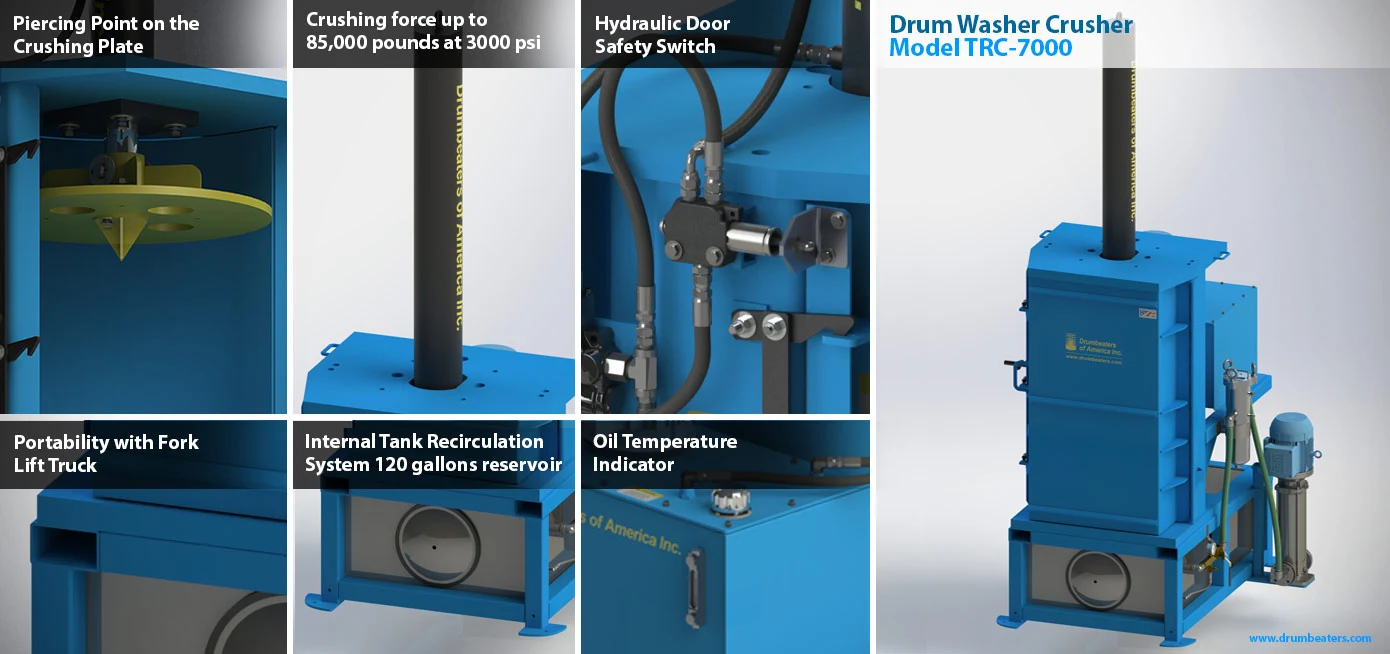

The Drum Washer Crusher Model TRC-7000 is a dual purpose machine. It can be used to wash drums or/and to crush the drum in the same chamber.

This system uses a high speed rotary nozzle for washing 100% of the interior of the drums. The TRC-7000 will crush a 55 gallon drum down to 2.5" in height greatly reducing storage space requirements and transport fees. The drum station is protected by a safety system to prevent the operator from activating a station when a drum is removed prior to the wash/crush cycle being finished.

All hydraulic, plumbing and electrical connections between the equipment components are included and based on the location of the equipment components.

This equipment is completely pre wired, pre plumbed, fully tested, and ready for operation. We build the equipment with engineered electrical plug connections and easy to assemble hoses for simple and easy installation.

The TRC-7000 model includes an internal recirculation tank system with 120 gallons capacity. You can increase the washing-crushing rate/performance by adding and external tank recirculation system (250, 500 or 1000 gallon capacity).

Proudly engineered, deleloped and assembled in the USA, each component of our drum crushers, drum washers and drum disposal equipment strictly adheres to American quality standards, ensuring superior reliability and performance for continuous heavy-duty services.

The TRC-7000 model includes an internal recirculation tank system with 120 gallons capacity. You can increase the washing-crushing rate/performance by adding and external tank recirculation system (250, 500 or 1000 gallon capacity)

Our Drum Washer Crushers are dual-purpose systems engineered to wash and crush steel drums automatically within the same chamber.

Collaborating with organizations of various sizes and spanning diverse industries worldwide, we have dedicated ourselves to our clients since our inception. Our commitment has led to notable successes and the establishment of enduring relationships.